In simple terms, electron beam welding is accomplished by heating a tungsten filament sending off a stream of electrons through an electro-magnetic field focusing then into a precise beam of energy less than .010” (0.254 mm) in diameter. As the beam strikes the work piece surface, using no filler and with heat concentrating up to 500 times that of conventional welding methods, electrons transform metal beneath the beam through a molten state to a gas allowing the beam to travel deeper and deeper. As the beam travels along, the small gas hole produced closes rapidly, and surrounding molten metal fuses causing minimal distortion and heat effect outside the weld zone.

Advantages of Electron Beam Welding

Advantages of Electron Beam Welding

- Total energy input is approximately 1/25 of conventional welding energy.

- Minimum distortion able to hold close tolerances.

- Beam control.

- Magnified optical viewing.

- Cost effective joining meets difficult design requirements and restraints.

- Low heat input. Pre-heating can usually be eliminated.

- Weld deep penetrations with extremely limited heat affected zones.

- High strength welds integrity (clean, strong, and consistent).

- Penetration control to within 5% of thickness.

- Contamination free welds.

- Joins similar and dissimilar metals.

- Repeatability (job to job/machine to machine).

- No fluxes or shielding gases to affect the properties of the weld.

- Little or no clean-up after welding – ready for N.D.T.

- Weld in areas that are impossible to reach with other process.

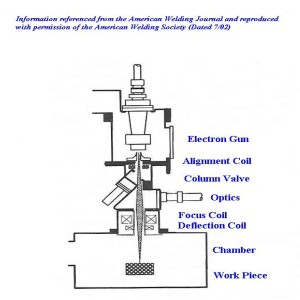

Conceptual Electron Beam Machine

Actual Electron Beam Machine

Full (CNC) Computer Numerical Controlled